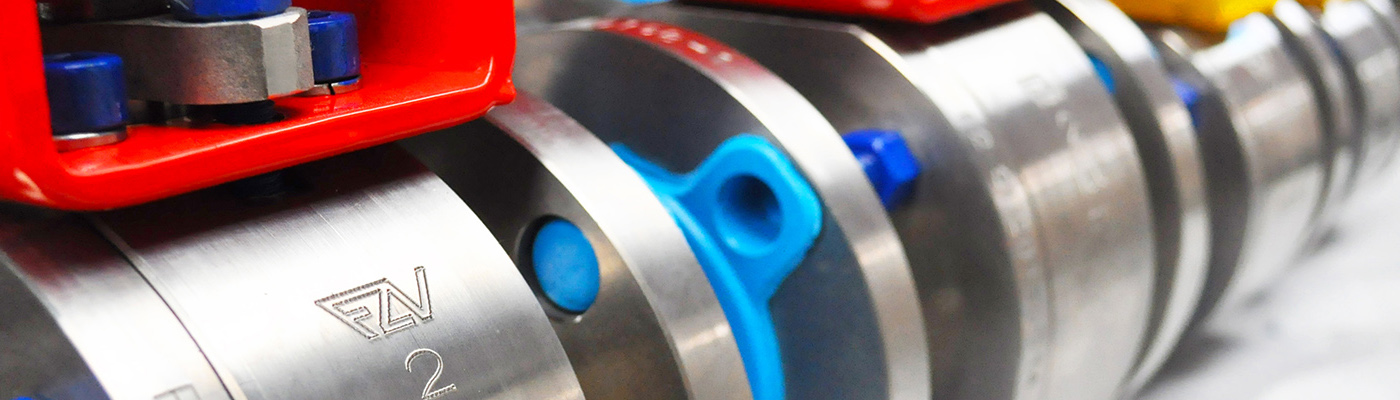

Cryogenic Butterfly Valve

Technical parameters and characteristics:

Product type | ON/OFF |

Product description | Cryogenic Butterfly Valve |

Model | DD343H-Cryogenic Butterfly Valve |

Nominal diameter | NPS 2”~48”(DN50~DN1200) |

Nominal diameter | -196℃~340℃ |

Nominal pressure | CLASS 150~900 (PN20~PN150) |

Material | Main material: A351 CF8、CF8M、CF3、CF3M;A352 LCB、LCC, etc. |

Design standard | API 609、ASME B16.34、BS 6364 |

Structural length | ASME B16.10、GB/T 12221、API 609 |

Connecting end | ASME B16.5、ASME B16.47、ASME B16.25、GB/T 9113 |

Test standard | API 598、ISO 5208、GB/T 26480、GB/T 13927、BS 6364 |

Operation method | Handle, worm, motor-drive unit, pneumatic drive unit |

Application fields | Low temperature industries such as LNG, LPG, LEG, air separation, etc. |

Other remarks 1 | The extension dimensions of valve stem and bonnet may vary according to different temperature ratings. |

Other remarks 2 | The main parts subject to a temperature ≤-101℃ are subzero treated to prevent valve deformation under ultra-low temperatures. |

Other remarks 3 | The sealing faces of valve seat and valve clack are build-up welded with hard alloy to improve the erosion resistance and extend the service life of valve. |

Other remarks 4 | Compact structure, easy installation and disassembly, repair friendly and light weight |

Other remarks 5 | It has a certain adjustment capability, and can be used as a control valve. |

Other remarks 6 | Good sealing performance of zero leakage |

Other remarks 7 | The sealing faces of valve seat and valve clack are build-up welded with hard alloy to improve the erosion resistance and extend the service life of valve. |

Other remarks 8 | Blow-off prevention design to ensure the operation safety |

Other remarks 9 | Drain board design to effectively prevent inflow of condensate to insulation layer |

Other remarks 10 | Low leakage packing is used for valve stem sealing to meet the requirement for low leakage. |